Products

Bone surgical appliances “Omega Drill”

Unique tip design delivers high-precision boring Patent NO. 6375469

Offers accurate and stable cutting even on a curved bone surfaces, eliminating “skiving”

The spiked tip immediately engages the bone surface and begins cutting, ensuring pinpoint precision even on a steep curved or a sloped bone surface.

Reduces clogging caused by bone debris after cutting

Since the cutting performance is the top priority in the drill design, bone debris can be smoothly discharged after cutting. The frequency of clogging has been significantly reduced.

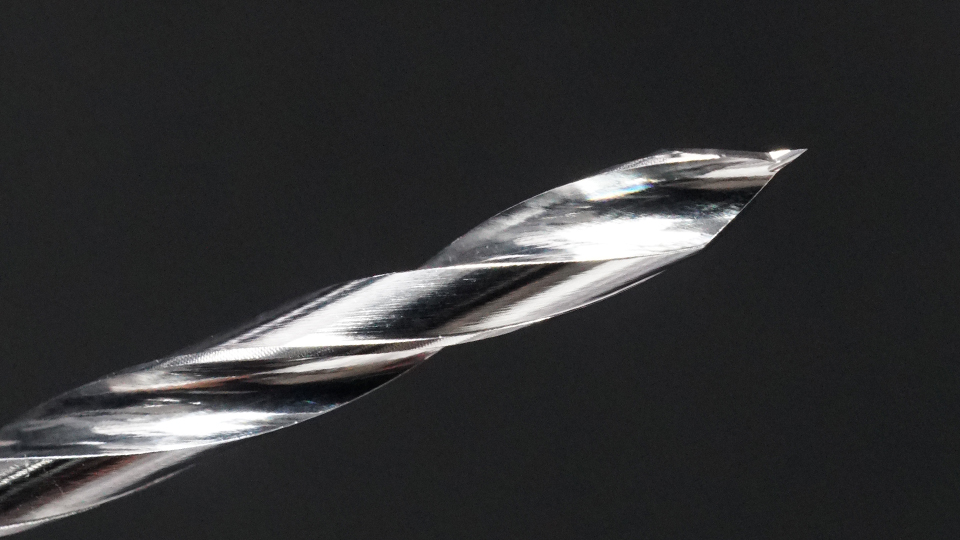

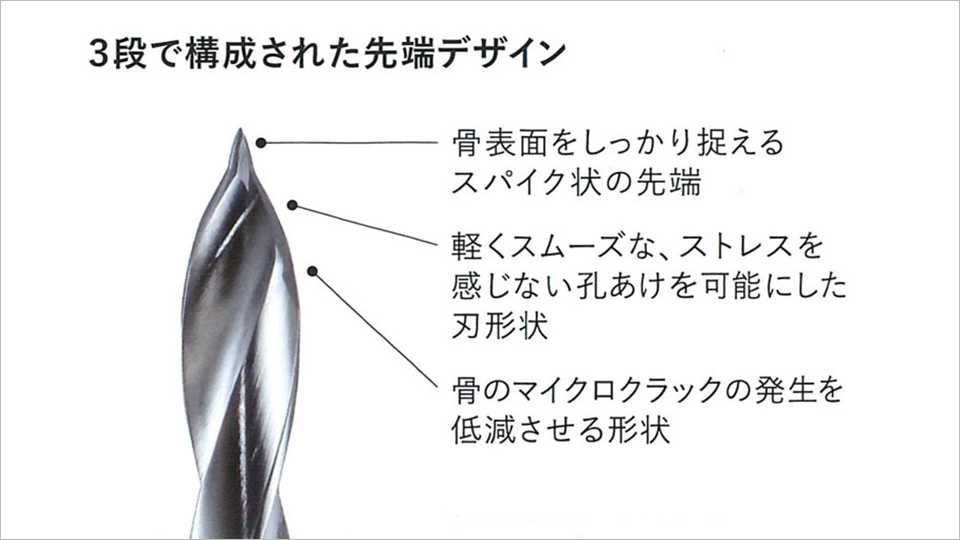

Three-step tip design

Patent No. 6375469 covers three elements invented by TOKO:

- Tip: Spike-shaped tip securely engages the bone surface

- Shoulder: Blade shape allows for easy, smooth drilling

- Body: Design reduces the occurrence of microcracks in the bone

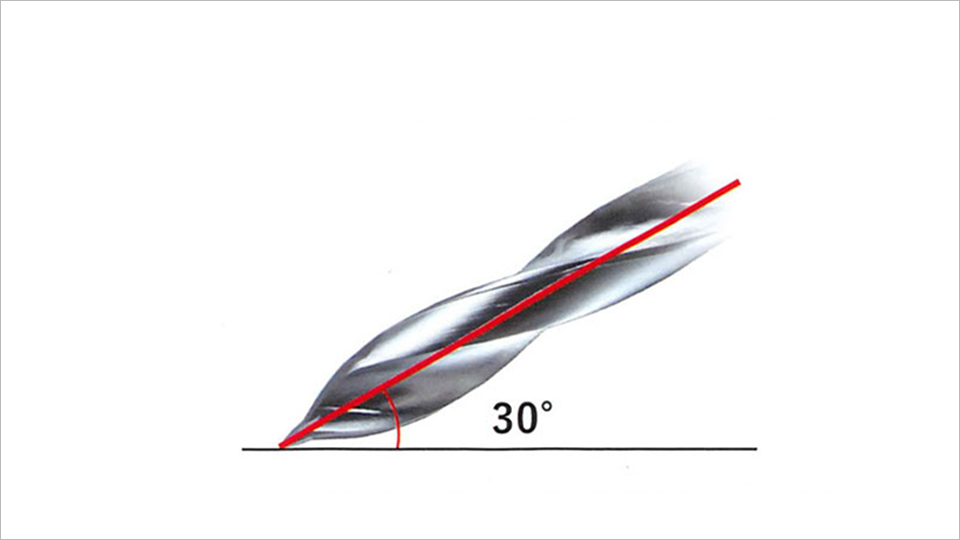

Engages bone surface firmly, even at extreme angles

The Omega Drill can operate at a minimum angle of incidence of 30°.

Reduced heat generation prevents tissue necrosis

A specially designed tip with high machinability allows precise drilling in the desired direction and enables operation at low rotation speeds.

Recommended use cases

- Bone surfaces with large slopes and/or curved surfaces

- Cortical bone in pediatric patients

- Peripheral bones of the hands and feet

- Cases that require high-precision hole angle and diameter

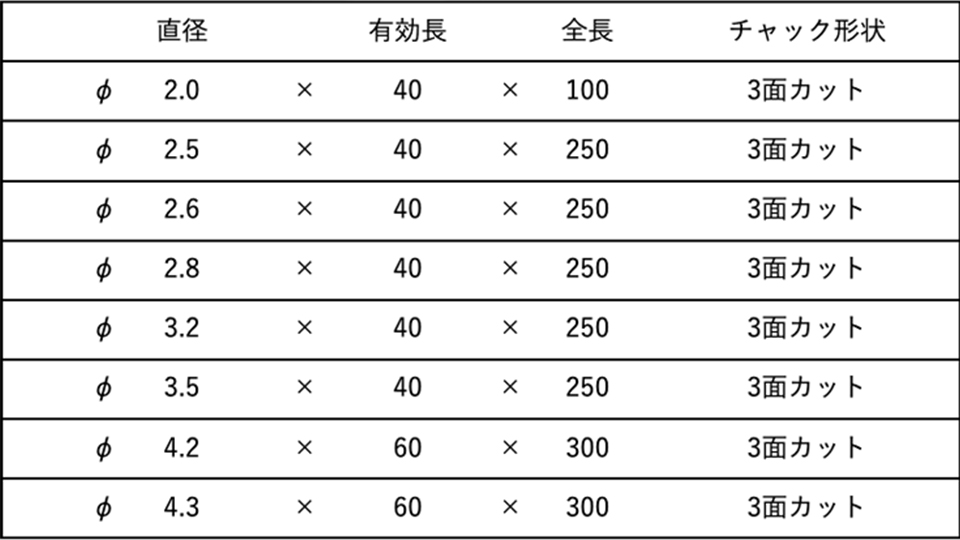

Omega Drill Size

Special orders for different sizes and chuck shapes are accepted. All products are reusable, and not intended for single-use.